High Speed Tool Steel Mechanical Properties

Tungsten high speed tool steels or group t steels range from t1 to t15 series.

High speed tool steel mechanical properties. Most tool steel properties require grades that suit heat treatment to achieve a high hardness. Basically the most important property of a high speed tool steel is its cutting ability. High speed steel is a subset of tool steels commonly used as cutting tool material. It is a steel gray metal that increases temperature and red hardness prevents gain growth and improves toughness of steels.

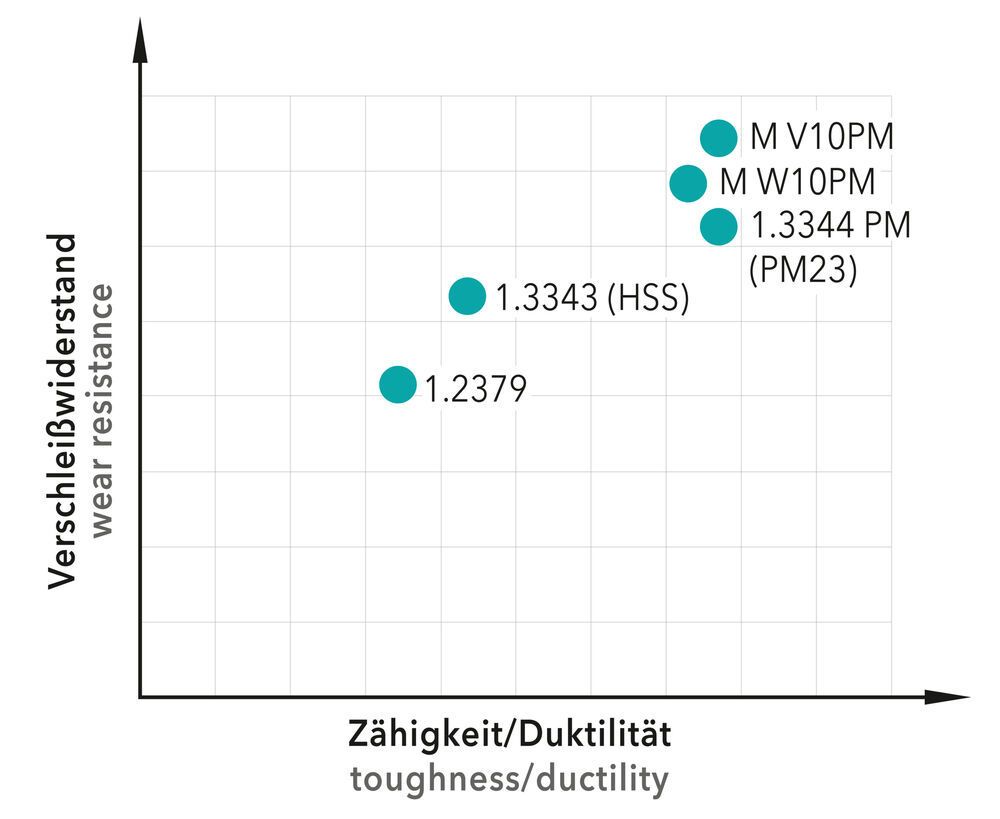

Their production by powder metallurgy pm techniques results in parts with a uniform distribution of carbides and therefore isotropic mechanical properties. This property allows hss to cut faster than high carbon steel hence the name high speed steel. In this study the process parameters which can achieve high speed manufacturing of h13 tool steel are. Relative properties physical properties.

0 284 lb in 3 7861 kg m 3 specific gravity. While all high speed tool steels have many similar mechanical and physical characteris tics the properties may vary widely due to changes in chemical composition. Tool steels are frequently used for the shaping of other materials. O1 tool steel is the original oil hardening non shrinking tool steel that can be hardened to the rockwell c 65 range from a low austenitizing temperature.

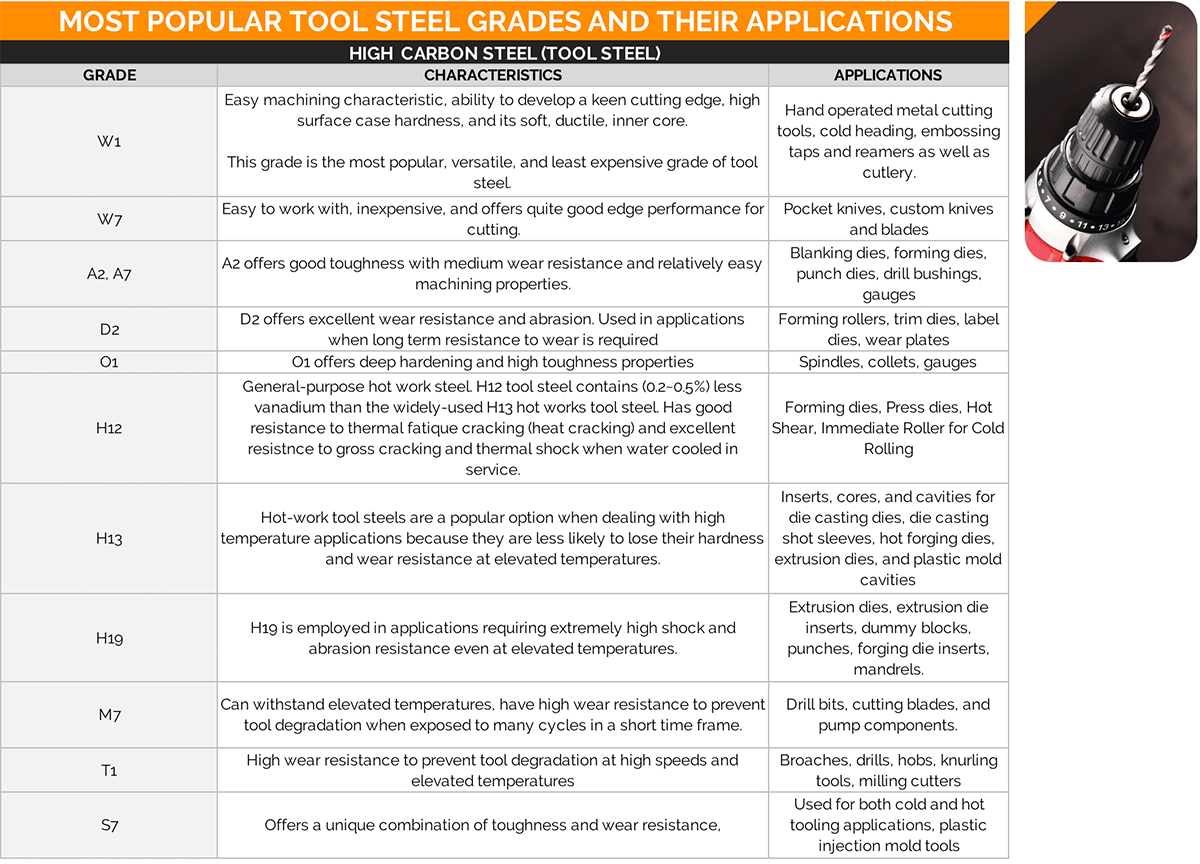

O1 is a general purpose tool steel that is typically used in applications where alloy steels cannot provide sufficient hardness strength and wear resistance. Tungsten is present in all types from m1 to m10 except m6 and cobalt is not present in any these steels. Popular types of tool steel include cold work hot work plastic mould and shock resisting which are used for a wide range of applications. It is often used in power saw blades and drill bits.

Tungsten is a good carbide former used in high speed steels and hot forming tool steels. Molybdenum high speed steels have similar performance when compared to tungsten high speed steels. 1 sem image of h13 tool steel powder. High speed steels have unique physical and mechanical properties that make them good candidates for the production of parts with an optimal combination of high strength wear resistance toughness and hardness.

At room temperature in their generally recommended heat treatment hss grades generally display high hardn. Heat treating instructions hardening. Table 1 chemical composition of h13 tool steel powder. 70 of a 1 carbon steel.

It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper. However the initial cost of molybdenum tool steels is lower.