Heat Treatment Process For Steel Purpose Modified Properties And Application

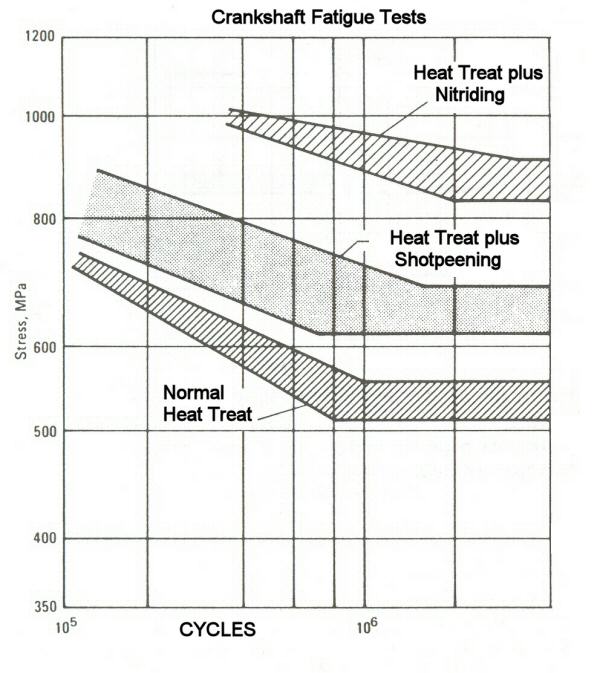

To increase the wear resistance of steel.

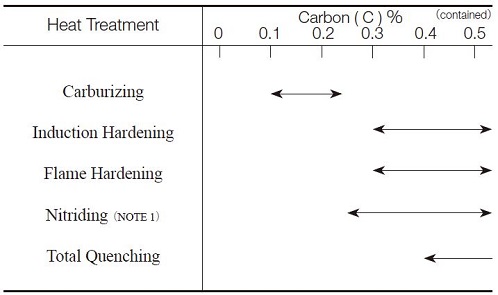

Heat treatment process for steel purpose modified properties and application. Improve the magnetizing properties. The heat treatment to secure uniform properties in this steel are. When heat treating steel other metals the various processes help make the metal more desirable for its application. This heat treatment process carried out for steel parts which have been already hardened in order to reduce bitterness and unequal stress develop as a result of hardening.

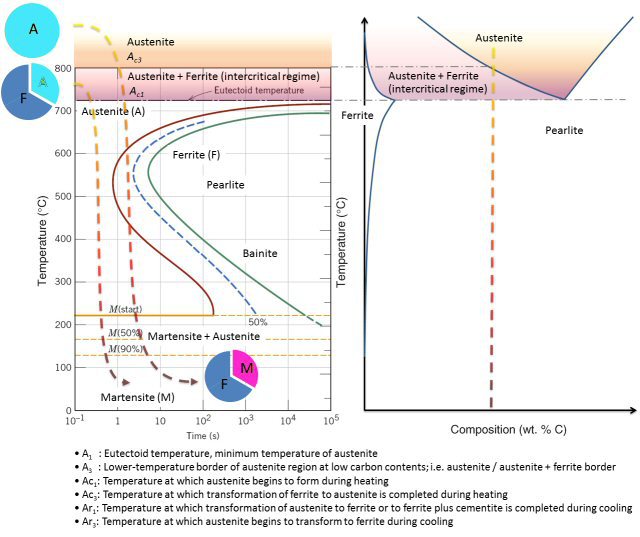

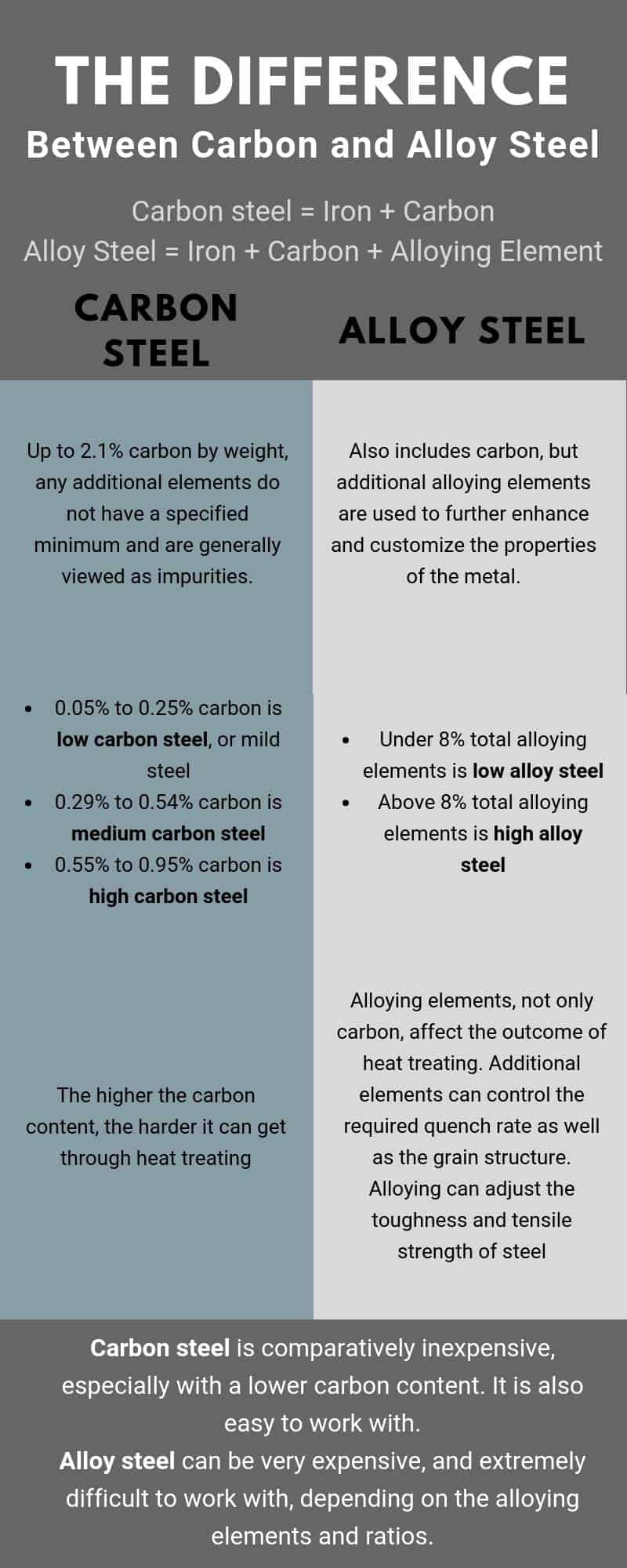

Heat treating or heat treatment is a group of industrial thermal and metalworking processes used to alter the physical and sometimes chemical properties of a material the most common application is metallurgical heat treatments are also used in the manufacture of many other materials such as glass heat treatment involves the use of heating or chilling normally to extreme temperatures. These heat treating applications are essential in the manufacturing process. The process of heat treatment is carried out to change the grain size to modify the structure of the material and to relieve the stresses set up the material after hot or cold working. Steel can be hardened to resist cutting action and prevent abrasion.

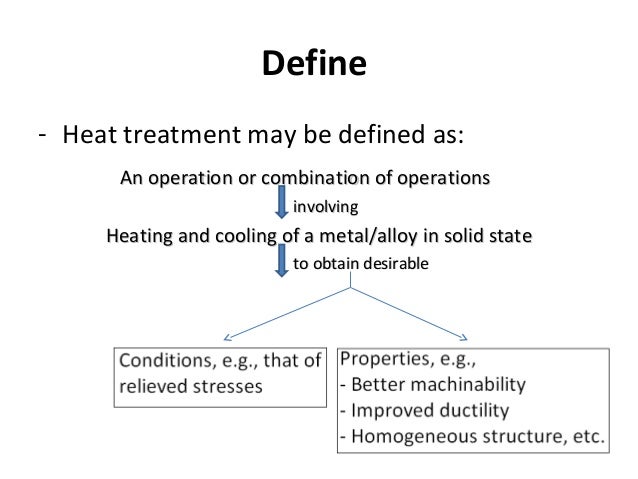

The mechanical properties such as ductility toughness strength hardness and tensile strength can easily be modified by heat treating the medium carbon steel to suit a particular design purpose. Heat treatment is the process of heating and cooling metals using specific predetermined methods to obtain desired properties both ferrous as well as non ferrous metals undergo heat treatment before putting them to use. Heat treatment is defined as an operation involving the heating and cooling of a metal or an alloy in the solid state to obtain certain desirable properties without change composition. This steel casting is very commonly used in railways.

Heat treatment not only increases the hardness but also increases the tensile strength and toughness. The rate of cooling and the manner of cooling are the controlling factor in heat treatment process. Precision steel breaks down the differences between the heat treatment processes including the common question of tempering vs annealing. And 0 025 s p maximum.

Heat treatment could be said to be a method for strengthening materials but could also be used to alter some mechanical properties such as improving formability machining etc. Over time a lot of different methods have been developed.