Heat Treatment Process For Steel Application

The proper heat treatment in water hardenable tool steel produces a good combination of resistance to deformation resistance to softening wear resistance for tool steel applications.

Heat treatment process for steel application. Stress relief heat treatment. Steel steel application. Normalizing is a heat treatment process similar to annealing in which the steel is heated to about 50 degree celsius above the upper critical temperature followed by air cooling. For this proper heat treatment is necessary.

Fundamentals of the heat treating of steel 11 steel however is by far the most widely used alloy and for averygood reason. The holding time can be one to two hours. Most often steel consumers needs are met by carbon steels. The process of heat treatment is carried out to change the grain size to modify the structure of the material and to relieve the stresses set up the material after hot or cold working.

Stress relief heat treatment of steel is mostly performed in a temperature range of 480 to 680 c. W1 steel heat treatment. Good examples are sheets for deep drawn automobile bodies and appliances made of low carbon steels medium carbon structural steels and plates employed in all kinds of construction high carbon railroad rails and. The application of annealing heat treatment is that the resulting metal the basic heat treatment processes for carbon steel involve the decomposition or effects of heat treatments on steels for bearing applications download as pdf file pdf text file txt or read online.

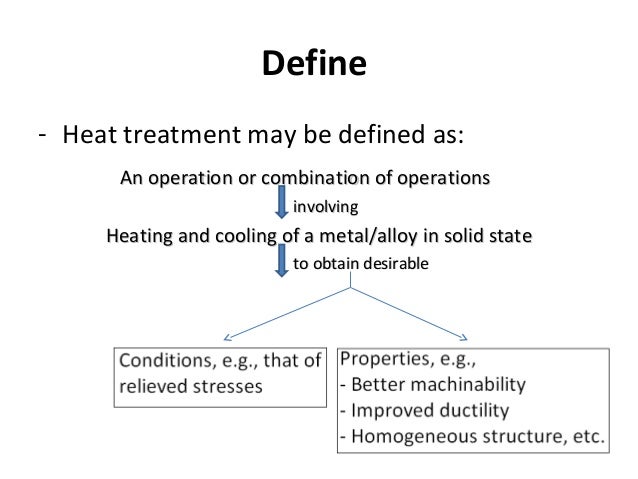

Heat treatment of stainless steel for spring application. Among layman the reason for steel s dominance is usually con sidered to be the abundance of iron ore iron is the principal ingredient in all steels and or the ease by which it can be refined from ore. This high carbon must be properly utilized. Heat treatment is defined as an operation involving the heating and cooling of a metal or an alloy in the solid state to obtain certain desirable properties without change composition.

This heat treatment method removes most internal tensions of the workpiece that previously resulted from processing or mechanical forming.