Heat Treatment Procedure For Steel Quenching

Face centered cubic phase of iron or steel.

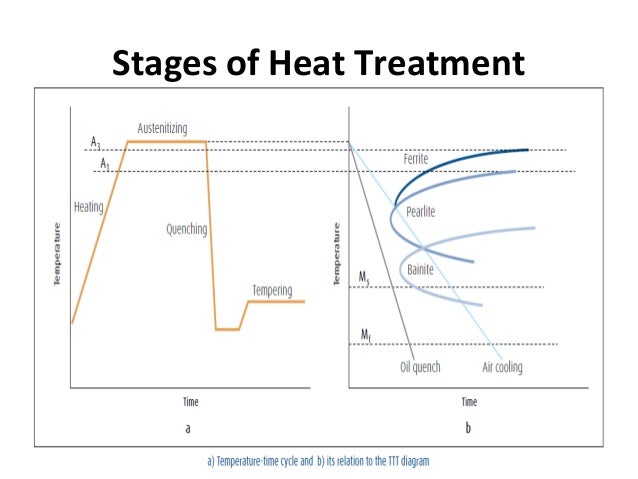

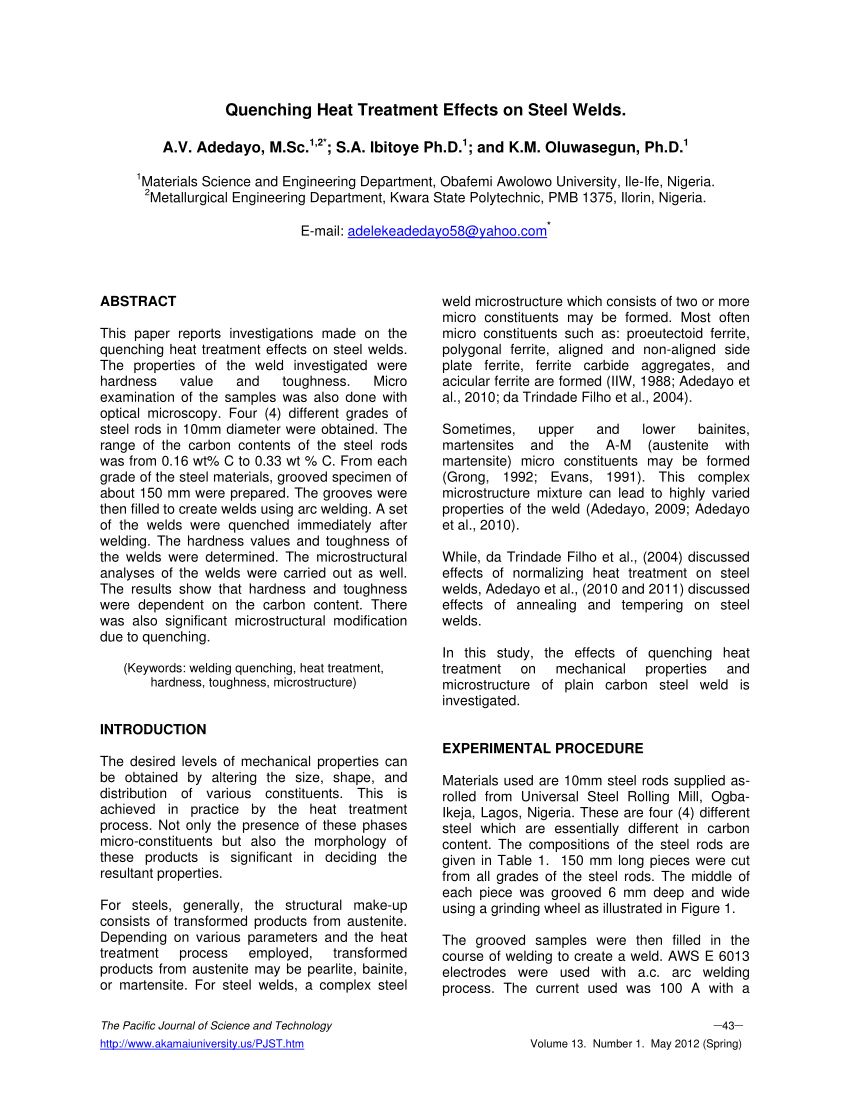

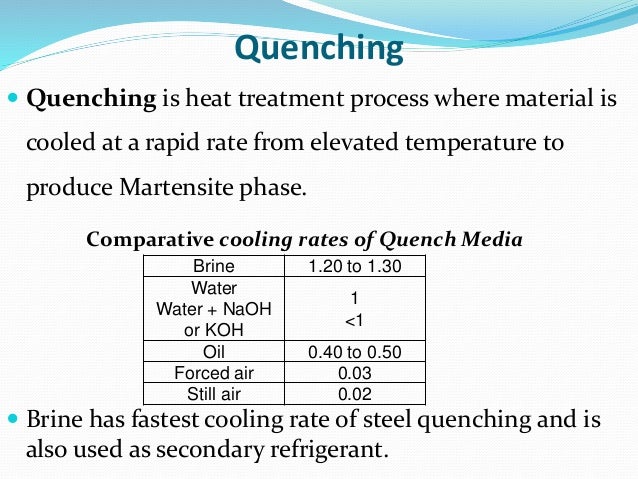

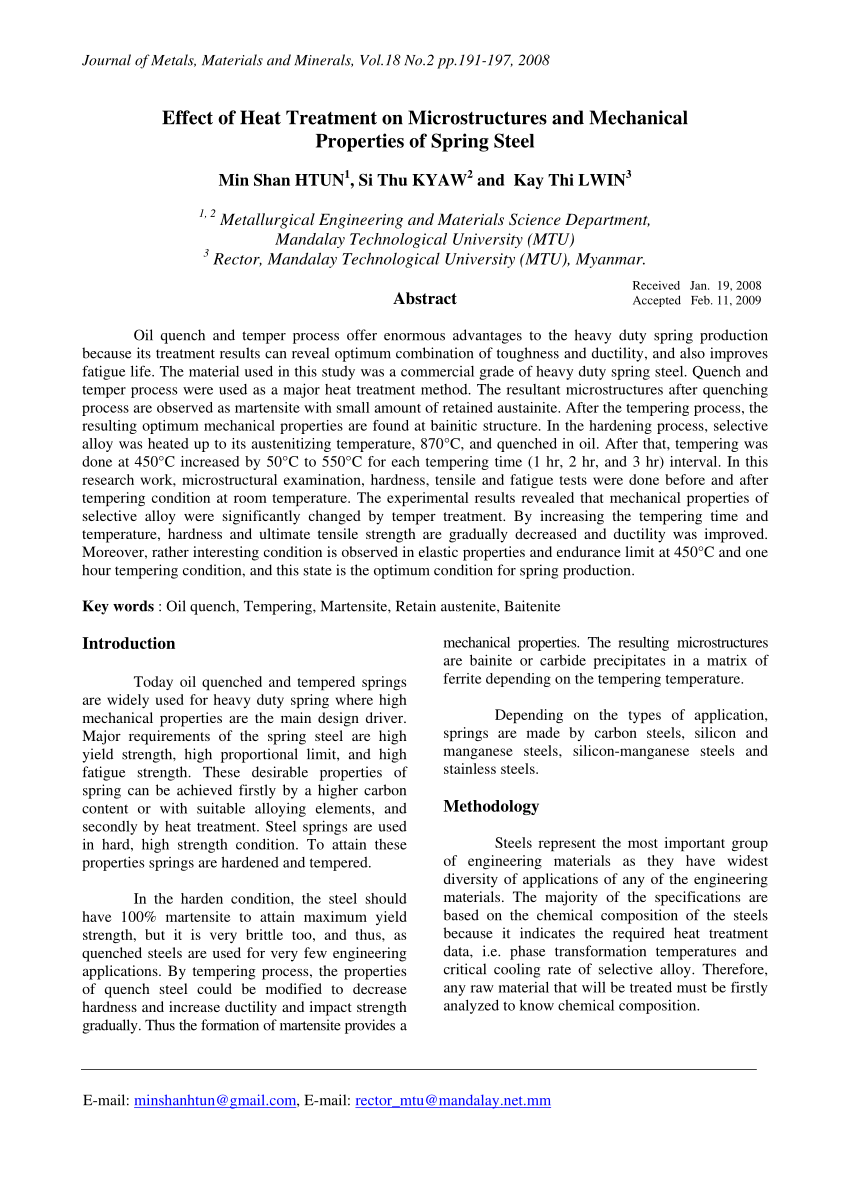

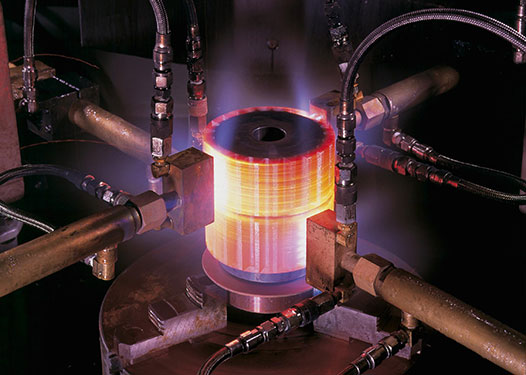

Heat treatment procedure for steel quenching. A simplified guide to heat treating tool steels when we consider that the greater overall costs of most tools and dies are incurred prior to heat treatment and further that proper heat treatment is critical to the successful application of tooling this so called hardening process is placed in it s proper perspective of importance. In materials science quenching is the rapid cooling of a workpiece in water oil or air to obtain certain material properties a type of heat treating quenching prevents undesired low temperature processes such as phase transformations from occurring. Austenitizing heating to above the gsk line into the austenite region. In order to influence the hardness and the strength of a steel a special heat treatment called quenching and tempering has been developed.

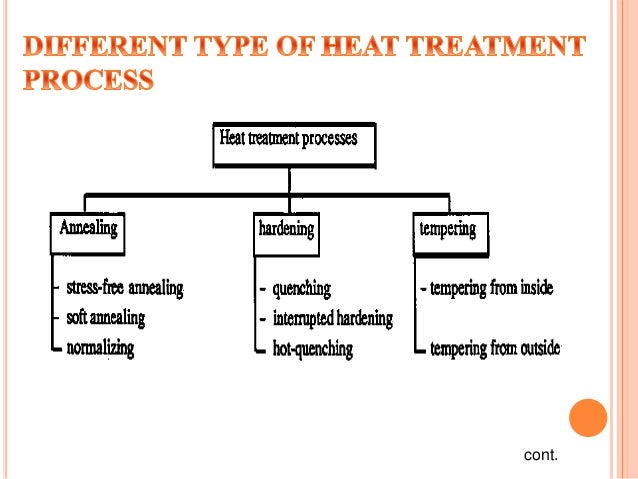

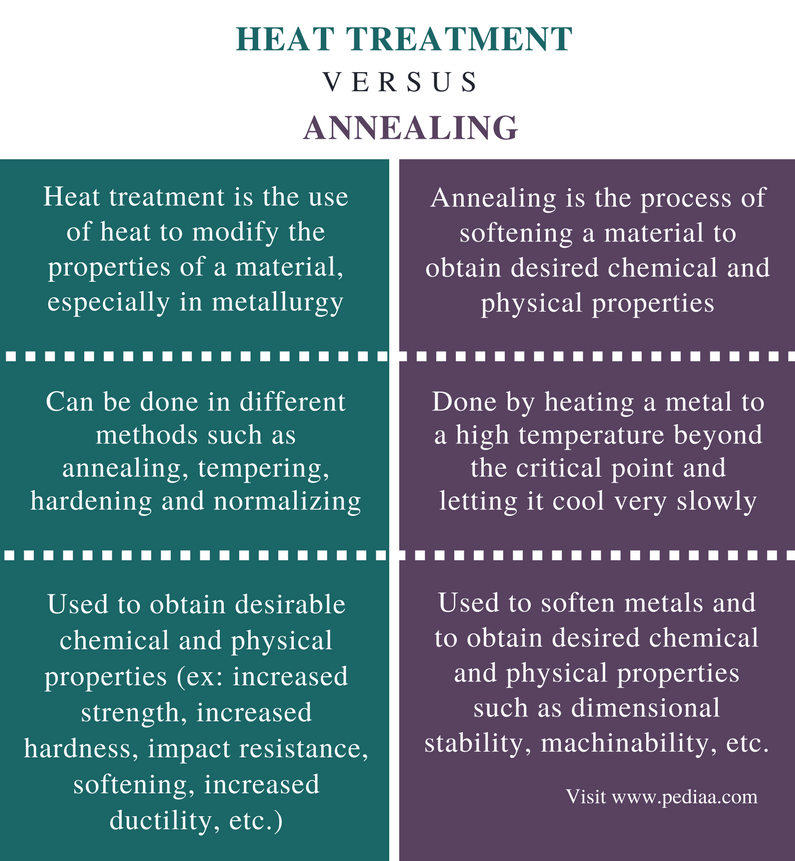

Austenitizing is the first step in most of the heat treatments for steel and cast irons. Quenching rapid cooling up below gamma alpha. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable and kinetically. A heat treatment used to produce a soft coarse pearlite in a steel by austenitizing then furnace cooling.

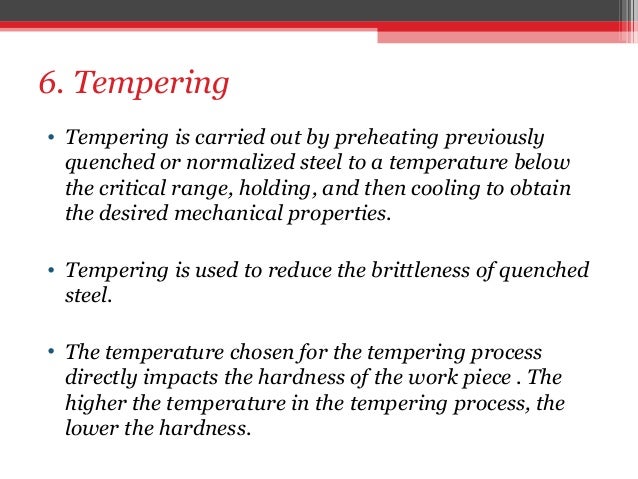

Normalizing is a heat treatment process similar to annealing in which the steel is heated to about 50 degree celsius above the upper critical temperature followed by air cooling. Quensching and tempering can be divided into three basic steps. The part is taken out and it does not require any quenching or further heat treatment. 4 2 procedure for tempering.

The steel has a high chromium content 11 to 13 percent and relatively high amounts of molybdenum 7 to 1 2 percent vanadium 1 1 percent cobalt 1 percent and other elements. Describe the proper heat treating procedures for other tool steels. This results in a softer state which will be lesser soft than that produced by annealing. The properties of a steel that has been quenched and then tempered depends largely on the rate of cooling and tempering times and.

When using 1045 steel room temperature water is used as the quenching medium. Temperature where homogeneous austenite can form. The steel after being quenched in the hardening process is reheated to a temperature slightly above the temperature range at which it is to be used but below the lower critical temperature. Quickly remove the steel from the furnace plunge it into a large container of water at room temperature and stir vigorously.

Conventional heat treatment procedures for producing martensitic steels generally involve continuous and rapid cooling of an austenitized specimen in some type of quenching medium such as water oil or air.