Heat Treatment Procedure For Steel Normalizing

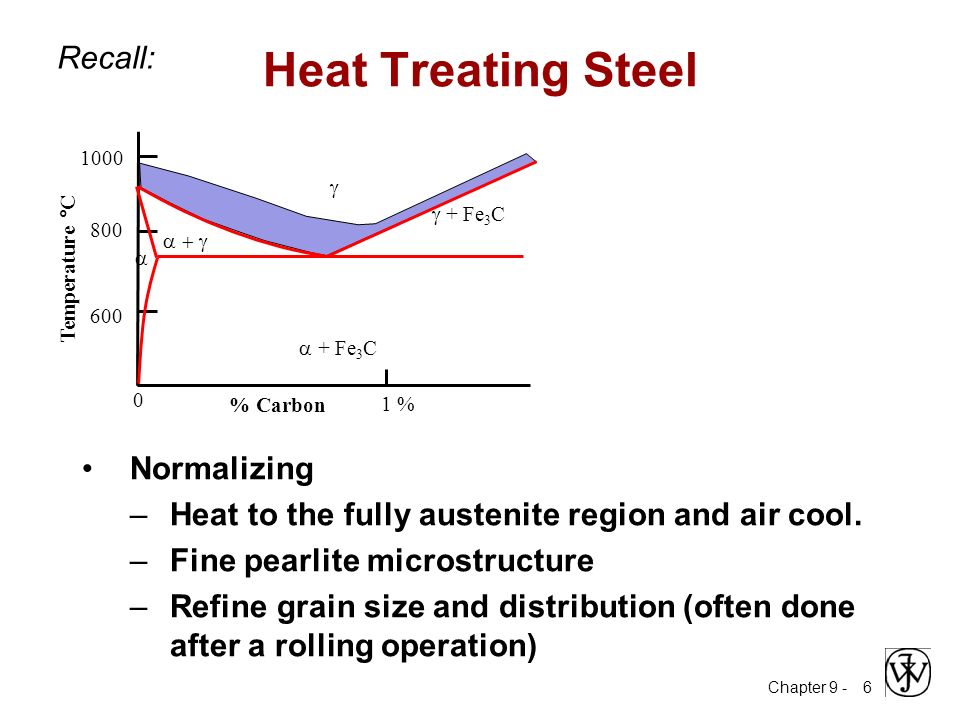

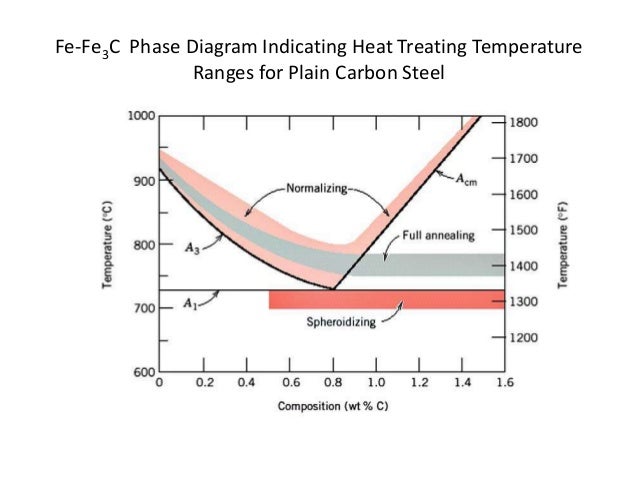

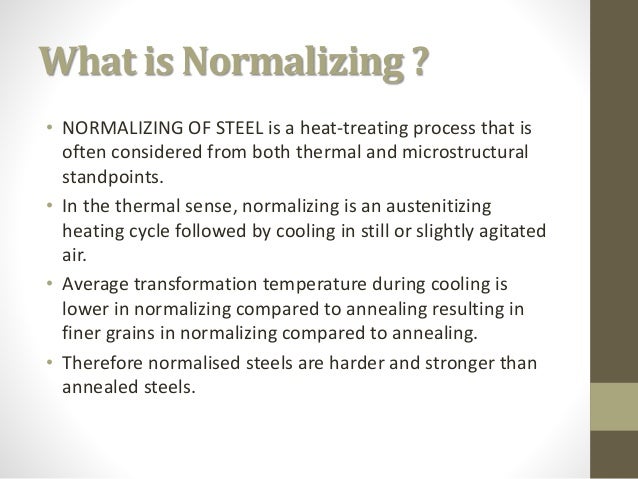

Normalizing heat treatment process is heating a steel above the critical temperature holding for a period of time long enough for transformation to occur and air cooling.

Heat treatment procedure for steel normalizing. Solution annealing sometimes referred to as quench anneal ing is an important category of annealing. Normalizing imparts both hardness and strength to iron and steel components. Normalizing also improves microstructural homogeneity and response to heat treatment e g. Since the cooling rate in the normalizing heat treatment is not controlled the resulting structure is dependent on the thickness of the steel work piece.

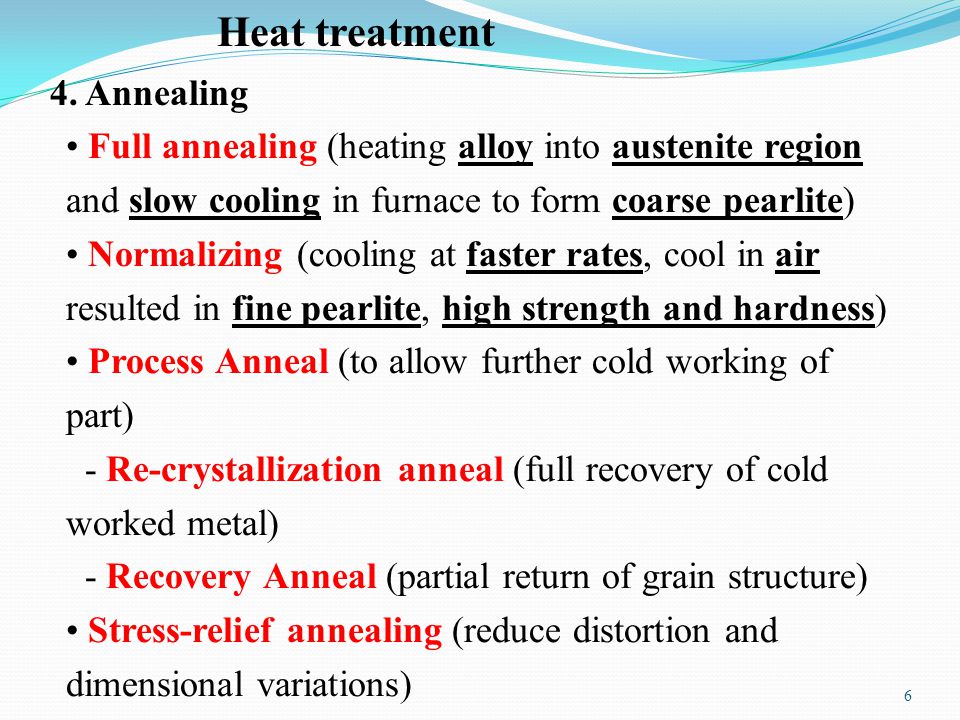

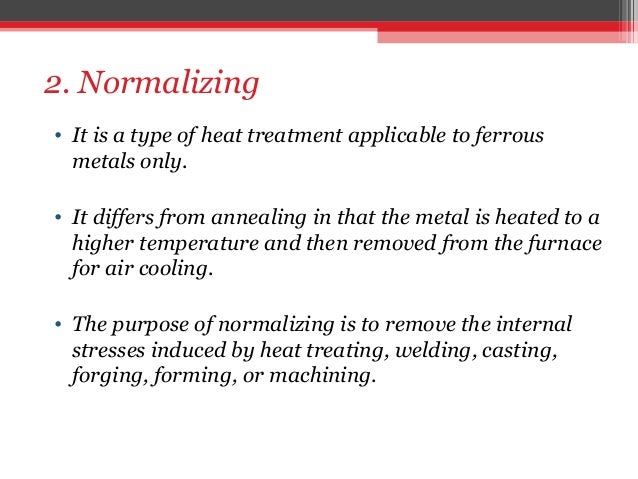

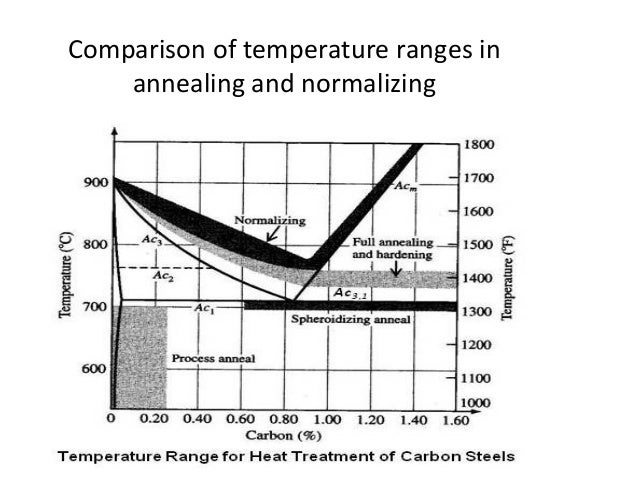

Normalizing is a heat treatment process similar to annealing in which the steel is heated to about 50 degree celsius above the upper critical temperature followed by air cooling. This results in a softer state which will be lesser soft than that produced by annealing. The process of heat treatment is carried out to change the grain size to modify the structure of the material and to relieve the stresses set up the material after hot or cold working. 1 induced by such operations as forging cast ing machining forming or welding.

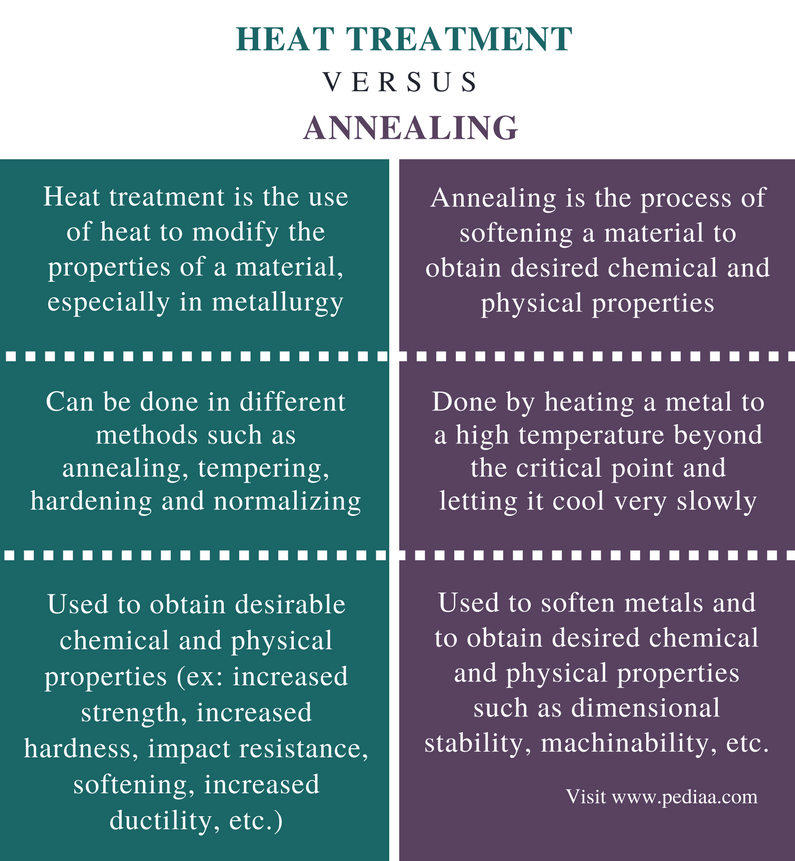

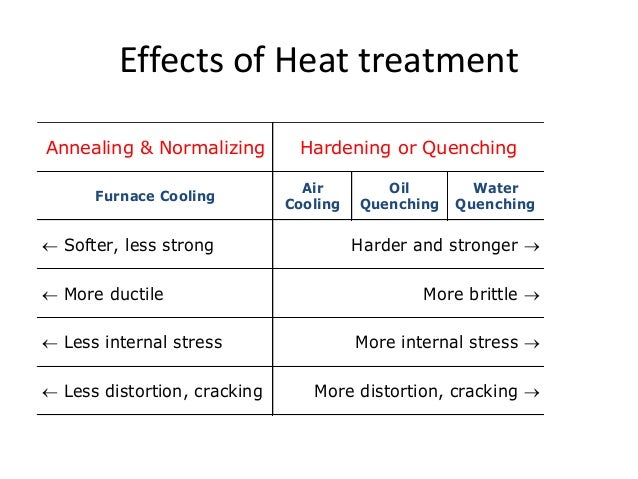

Heat treatment is defined as an operation involving the heating and cooling of a metal or an alloy in the solid state to obtain certain desirable properties without change composition. In addition normalizing helps reduce inter nal stresses fig. Normalized steel has higher hardness and strength than annealed steel due to the following reasons. Therefore the effect of increased mechanical properties is greater in thin work pieces.

The heat treatment is called solution annealing because the heat treatment takes. In the case of hot finished pipe no heat treatment is required. As during the. Heat treatment of pipe depends on the way it is manufactured hot finished or cold finished.

Normalized heat treatment establishes a more uniform carbide size and distribution which facilitates later heat treatment operations and produces a more uniform final product. Steel normalizing is a kind of heat treatment so understanding heat treatment is the first step in understanding steel normalizing. From there it isn t hard to understand what steel normalizing is and why it s a common part of the steel industry. Heat treating or heat treatment is a group of industrial thermal and metalworking processes used to alter the physical and sometimes chemical properties of a material the most common application is metallurgical heat treatments are also used in the manufacture of many other materials such as glass heat treatment involves the use of heating or chilling normally to extreme temperatures.

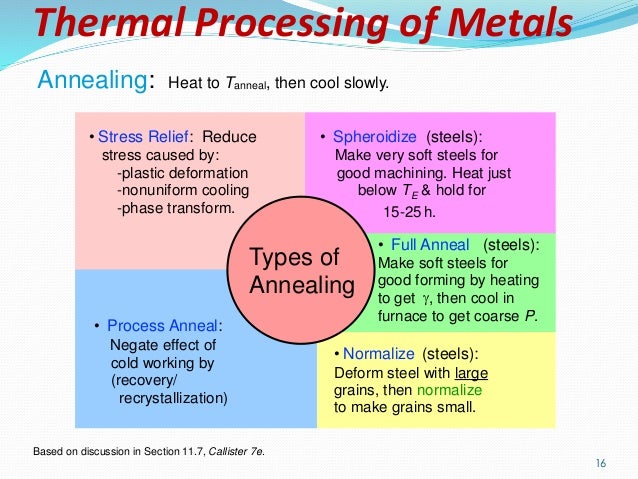

Some steel specific annealing heat treatments include normal izing spheroidizing and solution annealing which is described as follows.

.jpg)