Heat Treatment Of High Carbon Steel Wire Patenting

As shown in photo 1 the lamellas are coarsest in the stelmor cooled.

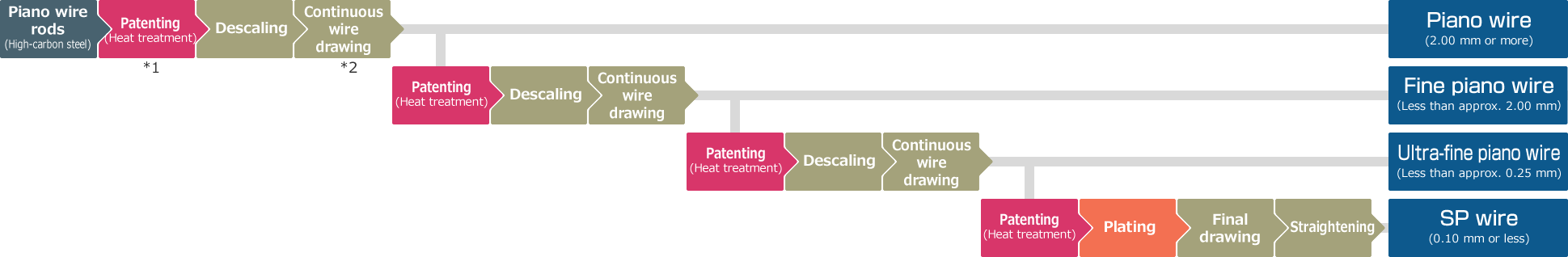

Heat treatment of high carbon steel wire patenting. Patenting consists of passing the wire through tubes in a furnace at about 970 o c. The patenting process developed in england involves running high carbon steel wires through tubes in a furnace heated to a temperature of 970 f then rapidly cooling the wire in air or molten lead. Photo 1 of the dlp wire rod is comparable to that of the lp wire rod the areashows the sem microstructures of a high carbon steel wire rod swrh 82b 11mmφ heat treated by dp stelmor cooling dlp direct in line patenting and lp lead patenting shown in fig. Solidly built and designed with a conservative heat flux the furnace has an extended pan life.

Normalizing carried for accomplishing one or more of the following. A process of heat treatment applied to medium or high carbon steel in wire making prior to the wire drawing or between drafts. This heat treatment process is usually carried for low and medium carbon steel as well as alloy steel to make the grain structure more uniform and relieve the internal stresses. Industry leading high velocity nozzle mix burners fire under the heavy walled steel pan in a staggered pattern.

It consists in heating to a temperature above the transformation range followed by cooling to a temperature below that range in air or in a bath of molten lead or salt maintained at a temperature. Patenting of steel wire is a common process whereby the wire is heated to 950 c to form austenite and then rapidly quenched in molten lead held at 500 c. Improve the machinability of low. The qed quench furnaces are built for the continuous rapid quenching of multiple in line steel wire strands in a patenting process.

This high temperature treatment produces uniform austenite of rather large grain size. Patenting consists of passing the wire through tubes in a furnace at about 970 o c. The optimization of lead patenting heat treatment process of high carbon steel wires is done using taguchi methodology. Reduce or remove internal stresses.

Tempering relieve ext stresses arising out of all hardened steel cold drawn wires cold working or hardening treatment case hardening increase wear resistance selectively on razor blade tools wire drg drums surface or edge patenting increase uts and drawability high carbon steel wires. The experiments have been carried out on an electric powered furnace in. Wire ropes for haulage purposes are usually made from carbon steel wires ranging from 0 35 to 0 5 carbon and before drawing the material is subject to a heat treatment known as patenting. The fine grained structure so formed patenting sorbite has high strength coupled with good ductility.

This has the effect of strengthening the wire without separating the iron from the other elements in the wire.