Hdpe Plastic Injection Molding Resin Pellets

We are hdpe and pp resin suppliers providing sustainable solutions to the world s largest brands.

Hdpe plastic injection molding resin pellets. With more than 100 million pounds of silo capacity and equipment to process over a billion pounds annually kw boasts the industry s largest capacities for blow. Through the use of high pressure the melted mixture is then put within a cooled mold for further development of the end product. Mixed color medium density polyethylene pellets are great for pipe plastic lumber furniture decking compression molding pipe profiles and. The high performance glow pigments in these pellets charge from sunlight incandescent bulbs or uv lamps and give off a bright green or a more subdued blue glow that lasts for a very long time.

Polymers with densities ranging from 941 to 965 and over are considered high density. Mixed color hdpe pellets frac melt. Overview of hdpe resin pellets. If you want to learn more about this process head over to our.

Birch plastics virgin resin sales division offers near prime high density polyethylene pellets hdpe. Injection molding high density polyethylene hdpe applications for hdpe injection molding resin include pails crates tote boxes housewares automotive hardware and sporting goods. Mixed color mdpe pellet 1 4 mfi. Where are these materials used and is rsp familiar with them.

Extrusion during the extrusion process resin pellets are once again heated and. Polyethylene is a common thermoplastic resin typically used for injection molding applications. These mixed color high density recycled polyethylene pellets are perfect for pipe plastic lumber furniture profiles and more. We provide common thermoplastic resin samples typically used for injection molding applications.

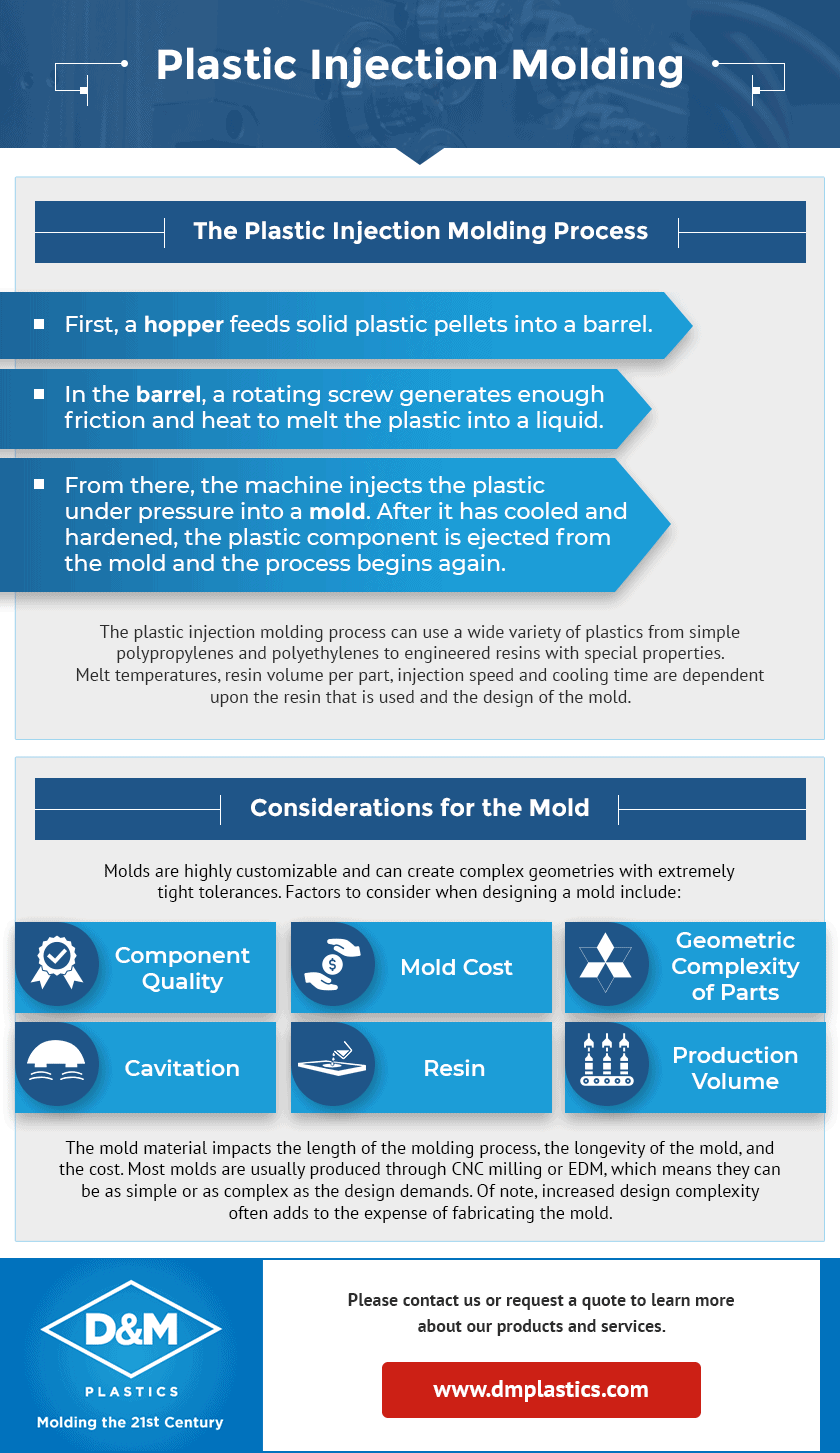

Injection molding during the injection molding process resin pellets are heated and then placed within a chamber for mixing. Kw plastics high density polyethylene hdpe resin comes in several varieties to meet the needs of any potential manufacturing applications. Although kw plastics is the world s largest plastics recycler for hdpe and pp we don t consider ourselves simply as recyclers. Professional plastics is the master distributor of vestakeep brand peek polyetheretherketone a high performance engineering plastics used extensively in medical semiconductor and aerospace materials.

Plastic resins and pellets for extrusion injection molding and compression molding are available from professional plastics. The pellets that all started as petroleum are used in injection and blow molding extrusion and other plastic manufacturing. Whether your application requires blow molding extrusion molding or injection molding our hdpe resins can be transformed into high quality hdpe materials and products.